Background information on the pole paddle system

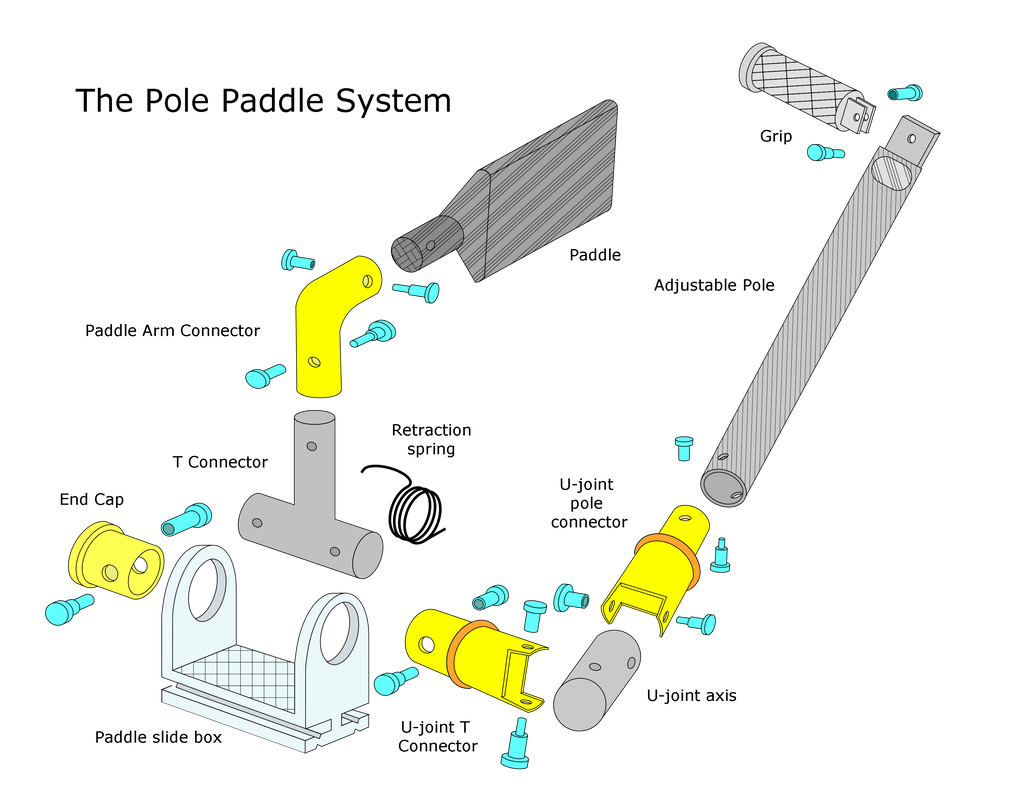

This is an early drawing of the Pole Paddle System. The paddle slide box slid in a custom designed track which at the time seemed to be a good design. A better design is highlighted below.

First generation prototype.

This is the first generation Supski made out of PVC for the rotating paddle arm and U-Joint and HDPE plastic sheets screwed together to make the track for sliding. The paddle slide box moved very smoothly. I used a 45 degree angle on this design but eventually adopted the ninety degree (I don't recall why). When the size of the track was reduced on the second generation prototype, I encountered a friction problem because of the rotational energy being applied to the mechanism to get the paddle into the water.

I added wheels to the paddle slide box to deal with the friction problem but ultimately the stainless steel wheels succumbed to the corrosion of the salt water.

This is the next generation board with the tracks built in. This is the video I showed you on my phone during our meeting.

The Retraction Spring Design

In this video I cover the problem of the need for a better retraction spring as well as how the mechanism works. As I stated before, the larger and heavier the paddle head size, the greater the effort is required to rotate the paddles out of the water at the end of each stroke. While smaller lightweight paddle heads don't require the use of a retraction spring, having two paddle heads the size of a paddle board paddle will give the user plenty of power and in theory should be faster than a regular paddle board.

The torsion spring will wrap around the rotating paddle arm and should solve the problem of an extension spring losing its tensile strength.

This video is similar to the one above but this was a 3D printed prototype. This ultimately is not a cost effective way to develop the product as far too many molds will be required to make all the parts.

This is a U-joint manufactured by Belden. They should have something we can incorporate into the mechanism.

New track design

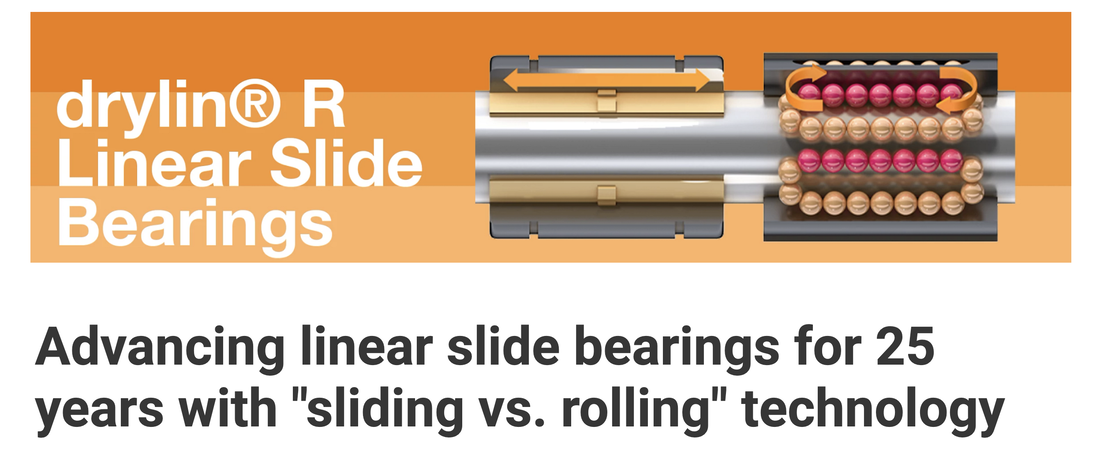

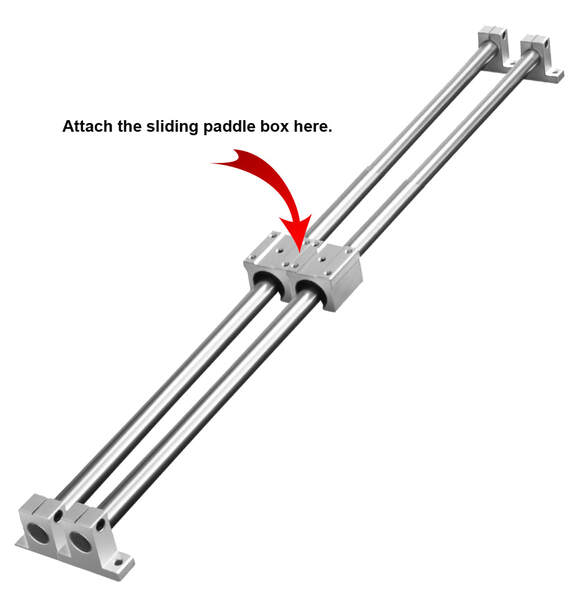

This is the design of the track that the Chinese manufacturer came up with for the Sliding Hand Paddle System we discussed on Wednesday afternoon. I thought it might be useful for the pole paddle system. While doing some research for the track I came across the drylin® R Linear Slide Bearings.

This is the demo video from the drylin website.

If we had two of the slide bearing shafts running parallel this would handle the rotational energy being applied and make for a smooth quiet operation.

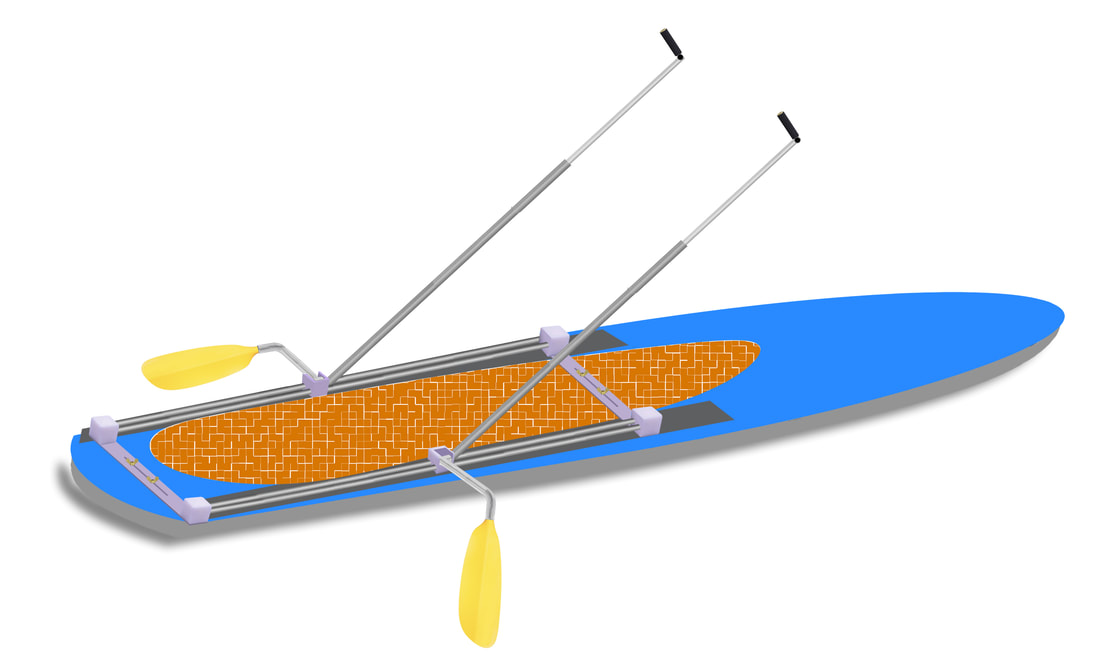

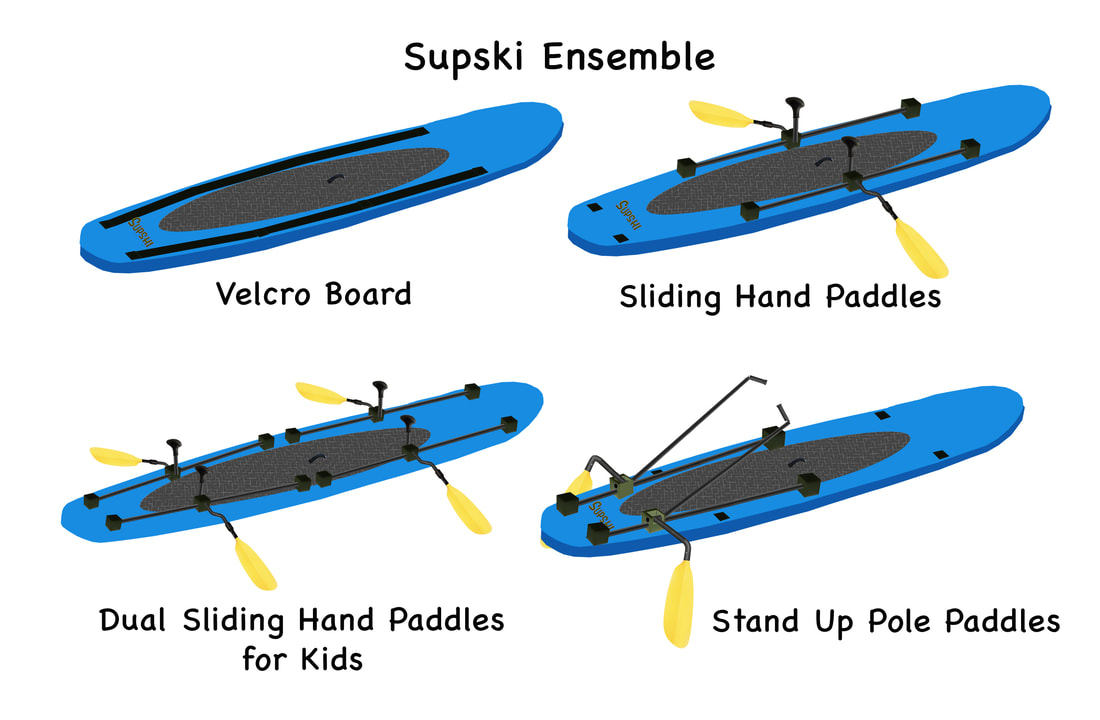

So this is the concept where the tracks would attach to adjustable plastic strips which would then attach to the paddle board with Velcro. If the customer doesn't want to modify their board, they can buy one of our Velcro boards.

My concept is the Velcro paddle board onto which you can attach the sliding hand paddles and the pole paddle system. It might be possible to have two smaller sliding hand paddle systems on one board for two kids.

Maybe the sliding hand paddles can be used on a kayak.

The manufacturer in China sent me this photo of the sliding hand paddles on a kayak but I never heard a word about any tests being conducted and as I told you he destroyed the prototype and never said exactly why.